furniture Arrangement App

Researchers at the Hasso Plattner Institute in Germany have created TrussFab, a new piece of software that turns digital 3D models into structures made from ordinary plastic bottles and 3D printed trusses.

Researchers at the Hasso Plattner Institute in Germany have created TrussFab, a new piece of software that turns digital 3D models into structures made from ordinary plastic bottles and 3D printed trusses.

Plastic bottles are everywhere. You’ll find them in the supermarket, in your fridge, and probably in your own hands at some point this week.

But bottles can also be found in places where they really don’t belong: in landfills, in the gutters of dirty streets, and even in the ocean.

Fortunately, the recycling of plastic bottles is becoming common practice. Many bottles are made from Polyethylene Terephthalate (PET) or High Density Polyethylene (HDPE), both of which are widely recycled, and the collected material from these bottles can be turned into new things—like .

Grinding a bottle down into shapeless plastic isn’t the only way to recycle it, though.

Researchers at Germany’s Hasso Plattner Institute have just gone one step further in the quest to turn used plastic bottles into useful objects, by creating a program that turns ordinary plastic bottles into large, interconnected structures.

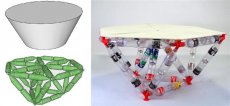

TrussFab, the researchers’ incredible new software, can automatically generated bottle-based structures from simple 3D designs using clever algorithms, and its possibilities seem virtually limitless. Need a new chair? Sketch it out in TrussFab and the application can show you exactly how to build one out of plastic bottles. How about a bridge capable of supporting a human’s weight? Again, the software is more than up to the task.

TrussFab, the researchers’ incredible new software, can automatically generated bottle-based structures from simple 3D designs using clever algorithms, and its possibilities seem virtually limitless. Need a new chair? Sketch it out in TrussFab and the application can show you exactly how to build one out of plastic bottles. How about a bridge capable of supporting a human’s weight? Again, the software is more than up to the task.

Described as “an integrated end-to-end system that allows users to fabricate large-scale structures that are sturdy enough to carry human weight, ” TrussFab actually concerns itself with more than just plastic bottles—it integrates 3D printing into the process too.

Bottles, of course, are not designed to be used as building blocks, but the Hasso Plattner researchers realized that 3D printing could be used to create structure-specific connectors or trusses that link multiple bottles in a secure way. TrussFab is able to automatically generate 3D printable files for these trusses, which then connect easily to the plastic bottles.

“Truss structures essentially consist of triangles, ” the researchers explain. “In such an arrangement, it is the structure that prevents de-formation, not the individual bottle.” According to these engineering experts, bottles are weak when pushed from the side, but “are very strong when pushed or pulled along their main axis.”

TrussFab takes advantage of this one-way strength by orienting each bottle so that forces are carried along its length, not across its weak sides. This ultimately produces “tetrahedral honeycomb structures” in which bottles are arranged in triangles to form strong, load-bearing units.

Amazingly, the Hasso Plattner researchers’ new TrussFab software is able to turn most 3D models into bottle-based structures in just a few simple steps.

First, an automatic conversion process turns a basic 3D model into a new 3D model consisting of bottles and trusses. Once this is done, users can use the TrussFab editor, created as an extension of SketchUp, to modify the design as they see fit.

First, an automatic conversion process turns a basic 3D model into a new 3D model consisting of bottles and trusses. Once this is done, users can use the TrussFab editor, created as an extension of SketchUp, to modify the design as they see fit.

Clever algorithms within the editor can determine whether a modified design is structurally viable: “TrussFab’s integrated structural analysis calculates the internal forces in the structure and warns users if it would [break], ” the researchers explain.

When a bottle-based design is finished, TrussFab is able to generate 3D printable files for every plastic truss required for the structure, and these files can then be sent to a 3D printer. Laser-cuttable 2D hubs for facades can also be generated.

And that’s only half the fun…

Once all plastic bottles have been sourced and trusses 3D printed, TrussFab users can kick on with assembly—probably the most rewarding part of the whole process. This is because the TrussFab software embosses unique IDs into each 3D or 2D printed hub, so you know exactly where it’s supposed to go.

Clearly, this design software sounds like a great use of plastic bottles (and time), but the question is: does it work?

Well, the Hasso Plattner researchers have already tested their amazing bottle-arranging software on a number of designs, including tables and chairs, a 2.5 m bridge that can support the weight of a human, a 5 m diameter dome consisting of 512 bottles, and a functional boat that seats two rowers.

And if the sight of two scientists rowing a bottle-based boat across a pond doesn’t convince you of the value of, surely nothing will.

“TrussFab embodies the required engineering knowledge, allowing non-engineers to design such structures and allows users to validate their designs using integrated structural analysis, ” the researchers say.

Related posts:

Decorating a too-large room can be as challenging as dealing with a space that is too small, but decorating a large room is a nice challenge to have! After all…

Decorating a too-large room can be as challenging as dealing with a space that is too small, but decorating a large room is a nice challenge to have! After all… Layout for Small Rooms Strip/Basic Home Office Layout. C. Roseberry Create a Functional and Organized Workspace Tired of working in your home office because it s…

Layout for Small Rooms Strip/Basic Home Office Layout. C. Roseberry Create a Functional and Organized Workspace Tired of working in your home office because it s… This cozied-up formal dining room is wonderful for those who have a large family or group of friends and often find themselves throwing dinner parties or hosting…

This cozied-up formal dining room is wonderful for those who have a large family or group of friends and often find themselves throwing dinner parties or hosting… According to Fast Company, Taco Bell is currently testing four new types of interior designs in Southern California, and they re really… well… something. There are…

According to Fast Company, Taco Bell is currently testing four new types of interior designs in Southern California, and they re really… well… something. There are… Schlafzimmer: Ideen, von der Einrichtung bis zur Deko Überlegen Sie sich vor dem Einrichten die Anordnung Ihrer Schlafzimmermöbel. Ist der perfekte Standort für…

Schlafzimmer: Ideen, von der Einrichtung bis zur Deko Überlegen Sie sich vor dem Einrichten die Anordnung Ihrer Schlafzimmermöbel. Ist der perfekte Standort für…